Polyurethane Materials

At its most basic, polyurethane foam moulding consists of processing the most appropriate materials and dispensing them into moulds, then allowing them to solidify or expand into foam, to produce individual items.

Whether you use foam for cushioning, insulation or the finest detailing, it’s vital to choose the right foam system, with the right density. At Mewett Polyurethane, we can provide a wide range of systems in different densities, from hard and rigid to soft and flexible.

Factors to consider include wear-resistance, conductivity and shore-hardness (degree of resistance to indentation). All of these can affect foam’s suitability for applications. Tear-strength is important when considering integral skin or cushion foam.

Foam can be pigmented or painted, depending on whether colour is integral to the product or is better applied externally. If required, we can give foam products increased UV stability, as well as anti-bacterial/flame-retardant properties.

We can also incorporate armatures (inserts) and other elements into the process.

The following foam systems are available:

Structural rigid foams

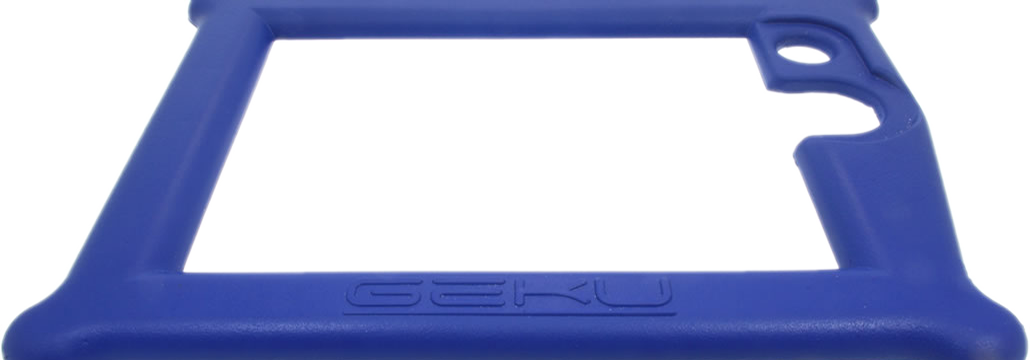

Structural foam moulding is a process that allows huge flexibility with the size and weight of structural parts. Though similar to injection moulding, this method uses much less pressure allowing components to have differing wall sections and characteristics. The end product tends to be lightweight and rigid with a relatively hard surface.

[More…]

Integral Skin Foams

Integral Skin Foam or “self skinning foam” usually comprise of a low density foamed core with a high density skin of the same material. This is achieved in a single moulding operation, where the foaming material forms a much tougher skin on impact with the contours of the cold mould.

[More…]

Insulation foams

Polyurethane insulation foam moulding uses polyurethane formulas with excellent thermal properties that create closed cell “air pockets” within the component when moulded. This makes the part ideal for shielding against high or low temperatures and is commonly used for cooling apparatus, like refrigerators and beer fonts, or heating appliances.

[More…]